Three in one: Knight Material Technologies leverages the expertise from three companies for sulfuric acid protection

Published by Leah Jones,

Digital Administrator

World Fertilizer,

Sulfuric acid corrosion has long been a significant challenge in the fertilizer industry, casting a corrosive shadow over the production and storage of essential agricultural compounds. Sulfuric acid is a key raw material used throughout fertilizer production, for example within nutrient formation and composition, pH adjustment, blending, and the initial acidulation of phosphate rock processing.

However, as a potent and highly reactive chemical agent, sulfuric acid also poses a persistent threat to the structural integrity of equipment, storage tanks, and pipelines crucial for fertilizer manufacturing and distribution. As a result, companies must develop successful strategies for dealing with the corrosion inherent in the process.

Within the past year, Knight Material Technologies (KMT) has expanded its capabilities through the acquisition of Electro Chemical Manufacturing (ECM) and its fluoropolymer subsidiary, Superior Dual Laminates, Inc. (SDL). By leveraging the unique expertise of each affiliated company, KMT has unveiled a one-stop destination for global corrosion protection, including materials required for use with phosphoric acid in fertilizer production.

ECM focuses on materials science and field service to protect and repair plant equipment with fluoropolymers, such as PVDF, ECTFE and PFA. Vessel linings can also be designed to include FRP dual laminate equipment from SDL, including piping, headers and specialty equipment. These methods provide robust protection when brick lining is unnecessary, or weight-bearing constraints are a concern.

In one case, a company experienced unplanned downtime when forced to stop production every two to three months to repair an elbow pipe responsible for venting sulfuric acid steam. The lining was under constant attack from sulfuric acid, and previous linings had resulted in pinholes, cracks and leaks due to the sulfuric acid itself, along with high temperatures, temperature fluctuations and vacuum pressures. The challenge was to install a protective layer that could withstand the chemical attacks of this highly corrosive environment while remaining lightweight, cost-effective and time-efficient.

ECM's solution was to apply an advanced PFA fluoropolymer that provided the proper elasticity without becoming brittle or cracking under elevated temperatures. The stronger lining also supplied a solution for the structural integrity issues often related to elevated temperatures. ECM's customer could now maintain a regular production schedule without unplanned shutdowns or frequent repairs.

Another common challenge for companies is finding competent field services for on-site repairs during planned shutdown preventive maintenance projects. With labour shortages of skilled technicians in many industries continuing to be a challenge, finding competent field service teams can be a true struggle.

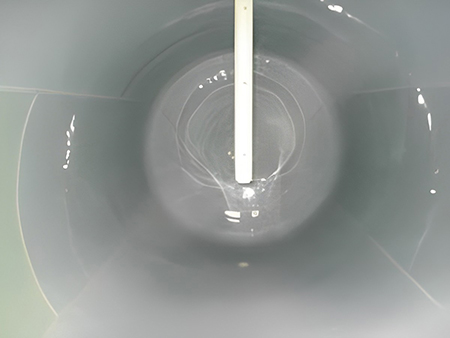

As a turnkey provider of both materials and field installation, KMT, ECM and SDL work with many customers to solve this labour and skill shortfall. In one planned shutdown project, ECM was tasked to reline a sulfuric acid storage tank.

To do the job, ECM stripped the vessel, repaired it, grit blasted it, and installed a polyvinylidene fluoride (PVDF) sheet lining system. A proprietary adhesive bonded the fluoropolymer to the substrate. This bond was tested in accordance with ASTM D-903 for secure adhesion. The proper adhesive and resulting bond help extend the lining surface life and reduces the risk of bulk storage tank failure.

Sometimes, repairs call for the design of a new substance to solve multiple challenges in heat, expansion and accessibility.

One example is KMT's EPOXIGARD™ HC injection, an injectable resin technology for sulfuric acid towers experiencing acid leaks in mortar, membranes and carbon steel shells.

This proprietary formula was a solution for the Noracid chemical plant located in Chile, which was experiencing leaks only weeks after a new brick-lined tower was installed. EPOXIGARD was the perfect solution for a situation where workers could not work within the tank.

Any injection of material would need to fill crevices completely through existing voids using low-pressure injection equipment and then harden and cure without creating new air passages. This required the injected substance to balance the proper consistency with efficacy. EPOXIGARD was inserted through holes detected by sounding. All the leaks were filled within ten days, and the plant was shortly back in production. Since this initial development and test case, EPOXIGARD has been used worldwide in other plants.

The affiliation and expertise of the three companies aligned under the KMT banner offer a comprehensive range of solutions, from brick-and-mortar linings to advanced fluoropolymer applications to end-to-end installation/repair services. Working hand-in-hand with its applications engineers and the customer's technical teams, KMT offers high levels of protection, engineering excellence and support for critical assets worldwide.

Read the article online at: https://www.worldfertilizer.com/special-reports/02102023/three-in-one-knight-material-technologies-leverages-the-expertise-from-three-companies-for-sulfuric-acid-protection/

You might also like

OCP Group officially launches ChemTechxAI innovation programme

OCP Group has officially launched ChemTechxAI, its open innovation programme at STATION F, France.

.jpg)